Table of Contents

Have you ever wondered, "Does cutting paper blunt knives?" It's a question that sparks debates among chefs, hobbyists, and anyone who values a sharp blade. The short answer is nuanced: it depends. This article dives into the surprisingly complex world of knife sharpness and paper cutting, exploring the factors that truly determine whether slicing through paper dulls your knives. We'll examine the surprising differences between various types of paper—from delicate tissue to thick cardboard—and how their abrasive properties affect your knife's edge. We'll also uncover the critical role that the material of your knife and its edge geometry play in its resilience against dulling. Finally, we'll equip you with practical tips and tricks for maintaining those razor-sharp edges, extending the life of your beloved knives even after countless paper cuts. Prepare to sharpen your knowledge on the age-old question: does cutting paper blunt knives? Let's get cutting!

The Great PaperCutting Knife Debate: Does Cutting Paper Blunt Knives?

The Great PaperCutting Knife Debate: Does Cutting Paper Blunt Knives?

The Age-Old Question

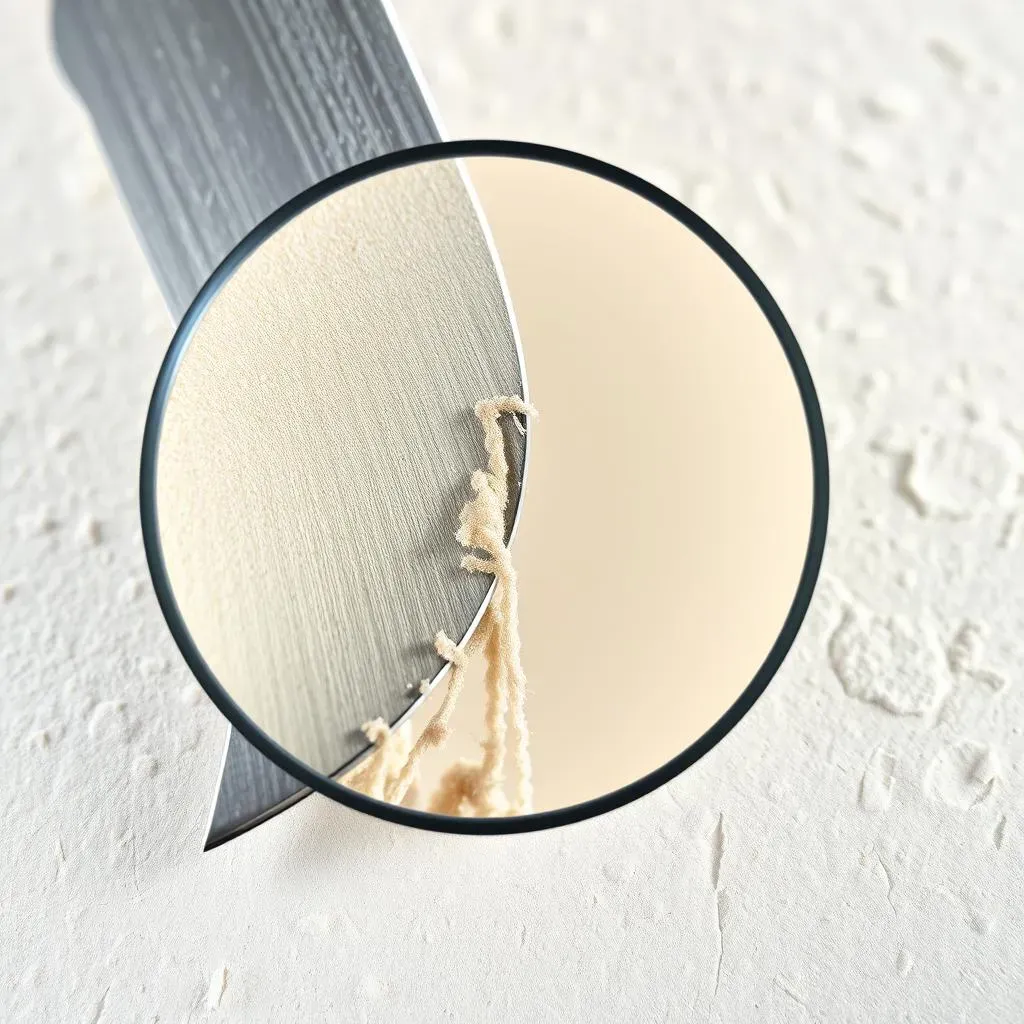

So, you're tackling the age-old question: does cutting paper dull knives? It's a surprisingly complex topic, isn't it? I remember when I first started researching this, I was convinced it was a simple yes or no answer. Boy, was I wrong! It's more like a tangled web of factors. The type of paper plays a huge role – think about the difference between cutting through delicate tissue paper and a thick piece of cardboard. One feels like butter, the other… well, let's just say it could test even the strongest blade. And then there's the knife itself. The material of the blade and the way it's sharpened also significantly impact its ability to withstand the wear and tear of repeated paper cuts. It’s not just about the sharpness; it's about the *type* of sharpness. For example, a knife designed for slicing delicate meats might not handle cardboard quite as well.

Let's not forget the importance of proper maintenance. Regular stropping and sharpening are crucial for keeping your knives in peak condition, regardless of what you're cutting. And even with the best care, some degree of dulling is inevitable. It's a bit like the wear and tear on your favorite pair of shoes – even the most durable ones will eventually show some signs of use. That said, understanding the nuances of how different paper types and knife materials interact is key to extending the life of your blades.

Paper Type | Abrasiveness | Effect on Knife |

|---|---|---|

Tissue Paper | Low | Minimal dulling |

Standard Printer Paper | Moderate | Noticeable dulling over time |

Cardboard | High | Significant dulling, potential chipping |

Think of it this way: imagine you're trying to cut through a piece of clay with a butter knife. It's not going to work very well, right? Similarly, some types of paper contain abrasives that can damage your knife's edge. We'll explore this further in the next section, but for now, let's just say that not all papers are created equal when it comes to knife friendliness. And if you're really serious about preserving your knife's edge, investing in a good quality honing steel or sharpening stone is a must. Learning how to properly sharpen your knives is a skill that will pay dividends in the long run. You can check out our guide on essential paper cutting tools for more information on sharpening your knives.

Speaking of sharpening, did you know that even the act of cutting through something as seemingly innocuous as paper can cause microscopic damage to your knife's edge? It's not always immediately obvious, but over time, this accumulation of tiny imperfections can lead to a noticeable dulling. It’s like a million tiny scratches, each one contributing to the overall degradation. This is why regular maintenance is so crucial. A dull knife is not only inefficient, but it can also be dangerous, making it more likely to slip and cause injury. Always prioritize safety when using sharp tools. And for those intricate paper-cutting projects, check out our amazing collection of paper cutting designs!

- Type of paper

- Knife material

- Sharpening technique

Understanding Abrasion: Why Some Paper Dull Knives Faster Than Others

Understanding Abrasion: Why Some Paper Dull Knives Faster Than Others

The Science of Abrasion

Let's get down to the nitty-gritty: why does some paper dull knives more than others? It all boils down to abrasion. Think of it like this: you're dragging your knife's edge across a surface. If that surface is smooth, like really smooth tissue paper, the damage is minimal. But if it's rough, like cardboard, it's like dragging your knife across sandpaper – ouch! The microscopic fibers and fillers in the paper act like tiny, abrasive particles, constantly wearing down the blade's edge. The more abrasive the paper, the faster the dulling. It’s a microscopic battle of attrition, with the paper's tiny particles slowly chipping away at the steel.

Different types of paper have varying levels of abrasiveness. For example, recycled paper often contains more filler particles, making it more abrasive than virgin paper. Similarly, paper with a higher clay content – think of some heavier, glossier papers – will dull your knife quicker. It’s not just about the texture you can feel; it's about the unseen microscopic structure. This is why some paper feels smooth to the touch but still causes wear and tear on your knife's edge. That seemingly innocent slice through a magazine could be slowly dulling your blade. Want to learn more about choosing the right paper for your projects? Check out our guide on choosing the right paper.

- Recycled paper

- Paper with clay fillers

- Cardboard

The Role of Fillers and Coatings

Now, let's talk about the hidden culprits in paper: fillers and coatings. Many papers contain fillers like clay or calcium carbonate to improve their smoothness, opacity, and printability. These fillers, while beneficial for printing, can be surprisingly abrasive to a knife's edge. They're often harder than the steel in many knives, acting like tiny, microscopic grinding stones. This is especially true for knives made from softer steels. Think of it like using a soft metal to cut through something harder – the softer metal will get damaged.

Coatings on paper, like those found on glossy magazines or coated cardboard, can also contribute to abrasion. These coatings are often harder than the paper itself and can significantly increase the abrasive effect on your knife's edge. So, while those shiny magazines might look impressive, they're not exactly your knife's best friend. It's a bit like trying to cut through a thin layer of plastic with your knife – the coating adds an extra layer of resistance that wears down the blade. For a detailed look at the tools you'll need for paper cutting, take a look at our guide on essential tools.

Paper Type | Filler | Abrasiveness |

|---|---|---|

Recycled Paper | Clay, Calcium Carbonate | High |

Glossy Magazine Paper | Coating | High |

Standard Printer Paper | Low | Moderate |

Minimizing Abrasion: Tips and Tricks

So, how can you minimize the abrasive effect of paper on your knives? First, be mindful of the types of paper you're cutting. If you're working with particularly abrasive materials like cardboard or heavily coated paper, consider using a less valuable knife or a utility blade. This will protect your more expensive and delicate knives. Second, use a cutting mat or cutting board. This will provide a more consistent and less abrasive cutting surface, protecting your knife’s edge. Think of it as giving your knife a softer landing.

Finally, regular sharpening and stropping are crucial. Even with careful cutting practices, some level of dulling is inevitable. Regular maintenance will help to keep your knives sharp and ready for any task. This will extend the life of your knives and keep them performing at their best. It's a small investment of time that pays off big in terms of efficiency and blade longevity. Discover more creative paper-cutting projects with our guide on easy creative ideas.

- Use a cutting mat

- Choose appropriate knives for the task

- Sharpen regularly

Knife Materials and Edge Geometry: Their Role in Paper Cutting

Steel Strength and Hardness: The Blade's Resilience

Let's talk about the knife itself! The material of your blade plays a huge role in how it handles the wear and tear of cutting paper. Harder steels, like those used in high-end chef's knives, are more resistant to dulling. Think of it like this: a harder steel is less likely to get scratched or chipped by the abrasive particles in the paper. Softer steels, however, are more susceptible to damage. They're more like soft butter, easily deformed by rough surfaces.

The hardness of a steel is usually measured on the Rockwell hardness scale. A higher Rockwell number means a harder steel. While harder steels resist dulling better, they can also be more brittle and prone to chipping if subjected to heavy impacts. It’s a trade-off: you gain resistance to dulling but might lose some toughness. Finding the right balance depends on how you use your knives. For intricate paper cutting, a moderately hard steel is often a good choice, balancing durability with sharpness. For more information on choosing the right tools, our guide on essential paper cutting tools is a great resource.

Steel Type | Hardness (approx. Rockwell) | Resistance to Dullness |

|---|---|---|

High Carbon Stainless Steel | 58-62 | High |

Carbon Steel | 60-65 | Very High |

Stainless Steel (lower grade) | 50-55 | Moderate |

Edge Geometry: The Shape of Sharpness

The shape of your knife's edge, or its geometry, also impacts its performance when cutting paper. Different edge geometries are designed for different tasks. A very sharp, thin edge is excellent for delicate slicing but can be more prone to damage when cutting abrasive materials. A thicker, more robust edge, on the other hand, will be less likely to chip or roll but might not be as sharp. It’s like choosing between a scalpel and a cleaver – each is best suited for specific tasks.

The angle of the bevel, or the angle at which the edge is ground, also influences its durability. A thinner bevel is sharper but more fragile, while a thicker bevel is more durable but less sharp. The choice depends on the balance you need between sharpness and toughness. For detailed paper cutting projects, a moderately thin bevel is usually preferred, offering a good combination of sharpness and resistance to damage. For more inspiration, explore our collection of intricate paper cutting designs.

- Thin Bevel: Sharper, but more fragile

- Thick Bevel: More durable, but less sharp

- Convex Edge: Durable and resistant to chipping

Maintaining Your Edge: Sharpening and Honing

Regardless of the steel and edge geometry, regular maintenance is crucial for keeping your knives sharp. Honing, which realigns the edge, is a quick and easy way to maintain sharpness between sharpenings. Think of it like combing your hair – it doesn’t cut your hair, but it keeps it looking neat and tidy. Sharpening, on the other hand, actually removes material from the blade to restore its edge. This is more involved and should be done less frequently.

The frequency of sharpening and honing depends on the type of steel, edge geometry, and how often you use your knives. However, regular maintenance is essential for keeping your knives performing at their best. A dull knife is not only inefficient but also dangerous. It’s like driving a car with worn-out tires – risky! Knowing how to properly sharpen and hone your knives will significantly extend their lifespan and keep them safe to use. For a deeper dive into the art of paper cutting, check out our guide on Chinese paper cutting.

- Regular honing: Maintains sharpness between sharpenings

- Periodic sharpening: Restores the edge

- Use a honing steel or sharpening stone

Maintaining Your Blades: Tips and Tricks to Keep Your Knives Sharp Despite Paper Cuts

The Importance of Regular Honing

Okay, so we've established that cutting paper *can* dull your knives, especially if you're dealing with abrasive types. But don't despair! The key to keeping your blades sharp despite regular paper-cutting adventures is consistent maintenance. Think of your knives like finely tuned instruments; they need regular attention to stay in top form. The first and most important step is honing. Honing realigns the microscopic teeth along the blade's edge, straightening them out after use. It's a quick and easy process that you can do frequently, even daily if you're a serious paper-cutter.

Imagine your knife's edge as a row of tiny soldiers. After cutting, some might be slightly bent or out of formation. Honing is like gently lining them back up, restoring their effectiveness. You can hone your knife using a honing steel, which is a long, slender rod with a slightly abrasive surface. Simply run the blade along the steel at a consistent angle, and you'll be amazed at how quickly you can restore sharpness. For more tips on maintaining your cutting tools, check out our guide to essential paper-cutting tools. It's a game-changer!

- Use a honing steel regularly

- Maintain a consistent angle while honing

- Honing should be done frequently, even daily

Sharpening: The Deep Clean for Your Blades

While honing is a quick fix, it's not a replacement for proper sharpening. Sharpening actually removes small amounts of material from the blade, creating a brand new, razor-sharp edge. Think of it as giving your knife a complete makeover. It's a more involved process, requiring a sharpening stone or a sharpening system, but it's essential for maintaining long-term sharpness. You won't need to do this as often as honing, perhaps every few weeks or months depending on your usage.

Sharpening is like giving your knife a spa day. It removes the microscopic damage that accumulates over time, restoring its cutting power. A sharp knife is not only more efficient but also safer. A dull knife is more likely to slip, leading to accidents. Investing in a good quality sharpening stone and learning the proper technique is an investment in both your safety and your craft. For some visually stunning paper-cutting projects, check out our selection of easy creative ideas and let your creativity flow!

Maintenance Task | Frequency | Tools |

|---|---|---|

Honing | Daily or weekly | Honing steel |

Sharpening | Monthly or bi-monthly | Sharpening stone or system |