Table of Contents

Ever wondered how stacks of paper get those perfectly straight edges? The answer often lies with the unsung hero of offices, classrooms, and print shops: the paper cutting guillotine. It's more than just a sharp blade; it's a tool with a history, a mechanism, and a purpose. In this article, we'll explore the world of the paper cutting guillotine, starting with its origins and moving through its modern applications. We’ll look at how these devices work, and the safety measures you should take when using one. I’ll also touch on different types, from the small ones you might see in an office to the large, industrial machines that process massive quantities of paper. We will go over the history of the paper cutting guillotine and how this tool evolved. So, whether you're a seasoned professional or just curious about how things are made, get ready to learn something new about this essential tool. It's time to cut to the chase and see what this paper cutting guillotine is all about.

The History of the Paper Cutting Guillotine

The History of the Paper Cutting Guillotine

The Dawn of Precision Cutting

Before the paper cutting guillotine, getting a clean, straight cut on a stack of paper was a real headache. Imagine trying to use scissors on a big pile – not pretty, right? People were using knives and other tools, but it was time-consuming, and the results were often uneven. Then, in 1844, a French inventor named Guillaume Massiquot thought, "There has to be a better way!" and he patented the first paper cutting machine that really resembled what we know today. It was a game changer, making it possible to make clean cut on paper more efficiently.

Evolution and Improvements

Massiquot's initial design wasn't perfect, of course. Like any good invention, it went through some upgrades. Over the years, other inventors tinkered with the design, making improvements to the blade, the clamping mechanism, and the overall structure. These changes made paper cutting guillotines more accurate and safer to use. The early models were hand-operated, requiring some muscle, but eventually, we got to the point where machines could do a lot of the work for us. It's pretty wild to think about how something so simple has changed over time, making it easier to create everything from books to flyers.

Inventor | Year | Contribution |

|---|---|---|

Guillaume Massiquot | 1844 | Patented the first paper cutting machine. |

Various Inventors | Late 19th - 20th Century | Improved blade design, clamping mechanisms, and safety features. |

How a Paper Guillotine Works

How a Paper Guillotine Works

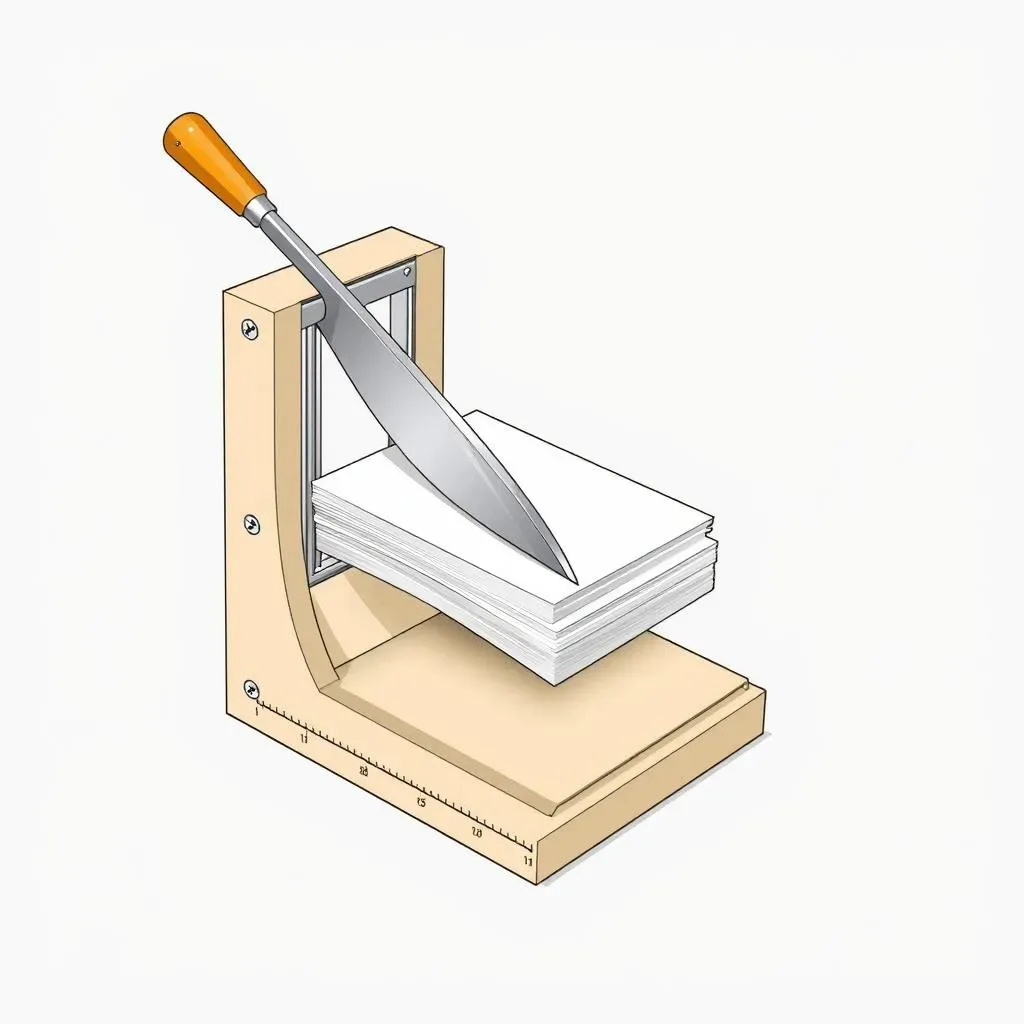

The Basic Setup

Okay, so let's break down how this paper-slicing machine actually works. It's not rocket science, but it is pretty clever. You've got a flat base, right? Think of it like a table for your paper. This base usually has markings on it, a grid and a ruler, to help you line up your paper correctly. Then, there's the star of the show: the blade. It's a curved piece of steel, super sharp, attached to a handle. This handle is what you use to bring the blade down to make the cut.

Before the blade does its job, the paper is held down to prevent it from moving. Some guillotines have a manual clamp that you tighten yourself. Others have an automatic clamp that engages as the blade moves. This clamp is crucial because it ensures the cut is straight and clean. Without the clamp, the paper would shift, and you'd end up with a jagged edge. The whole process relies on these parts working together smoothly, creating a precise cut every time.

The Cutting Action

So, you've got your paper lined up, and the clamp is holding it steady. Now, it's time for the cut. You push down on the handle, and the curved blade comes down in a smooth, slicing motion. It’s like a super-powered knife, but instead of moving back and forth, it moves in an arc, cutting through the paper. This slicing action is what gives you that clean edge. The blade moves past a metal edge on the base which is the cutting edge that it cuts against.

The design of the blade and the way it moves is crucial for a good cut. The curve of the blade helps it slice through the paper with less resistance. The handle gives you the leverage you need to cut through multiple sheets at once. Some guillotines are designed to cut through just a few sheets, while others can handle hundreds. It all comes down to the power of the blade, the clamp, and the way it all works together. It’s pretty satisfying to watch it in action, especially when you get a perfect cut.

Component | Function |

|---|---|

Base | Provides a flat surface and guidelines for alignment. |

Blade | Sharp, curved steel for slicing through paper. |

Handle | Lever for bringing the blade down. |

Clamp | Holds paper firmly in place during the cut. |

Safety First: Using a Paper Cutting Guillotine

Safety First: Using a Paper Cutting Guillotine

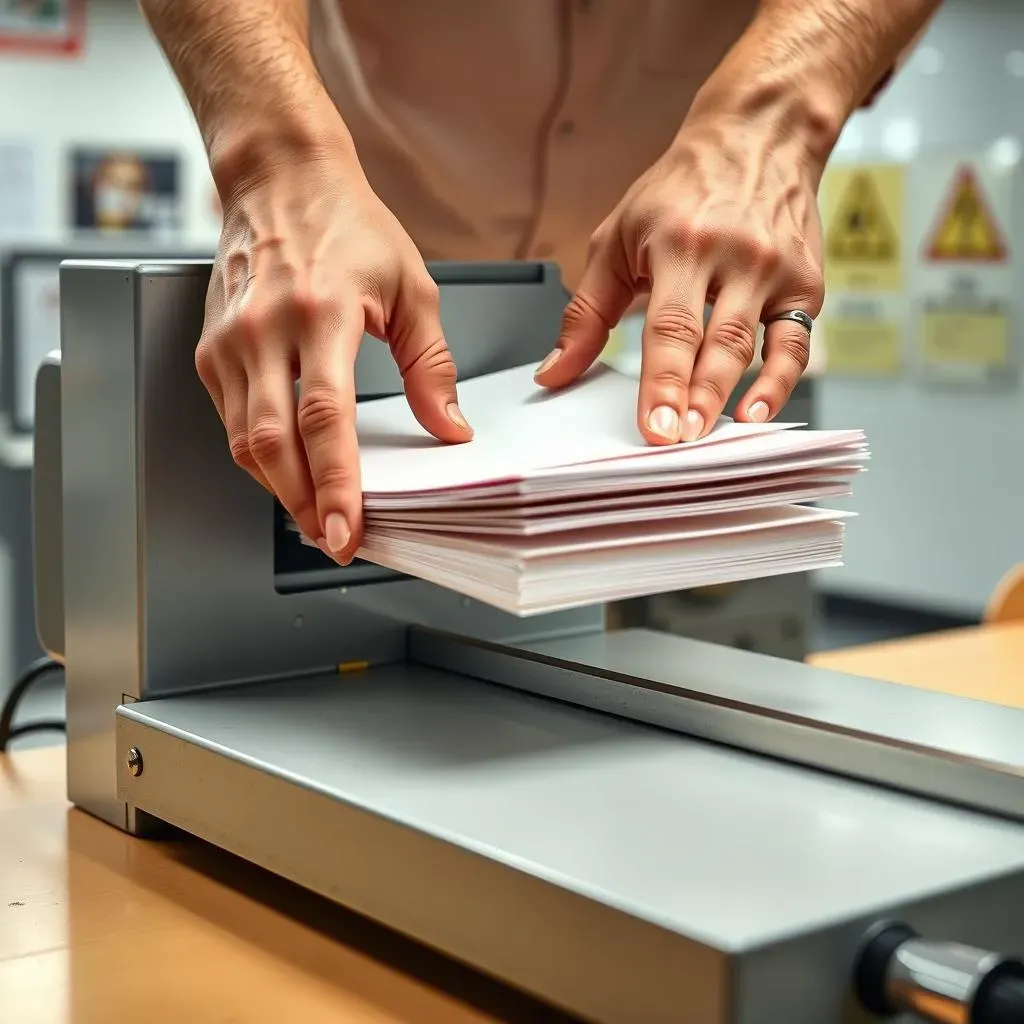

Alright, let’s talk safety because, let’s face it, a paper cutting guillotine is essentially a big, sharp blade. It's not something you want to mess around with carelessly. I've seen people get a little too comfortable with these things, and that's when accidents happen. The key is to treat it with respect and always be mindful of what you're doing. First things first, always, always keep your fingers clear of the blade's path. I know it sounds obvious, but it's easy to get distracted and forget. Before you even think about making a cut, make sure the area is clear of anything that could get in the way, that includes your fingers and hands.

Another important thing is to never try to cut more paper than the guillotine is designed for. Overloading it is a recipe for disaster. It can cause the blade to jam, or worse, it can cause the whole machine to break, and that blade can become very dangerous. And hey, if you're using a guillotine with a manual clamp, make sure you tighten it properly. A loose clamp means the paper can shift, and you won't get a straight cut, and it's also a safety hazard. Always double-check that the paper is secure before you make your cut. This is not something you want to rush; take your time, and be deliberate about each step. Remember, a moment of carelessness can lead to an injury, and nobody wants that.

Safety Rule | Why It's Important |

|---|---|

Keep fingers clear of the blade path | Prevents cuts and injuries. |

Don't overload the guillotine | Avoids jams and machine damage. |

Tighten manual clamps properly | Ensures paper doesn't shift, preventing uneven cuts and injuries. |

Focus and avoid distractions | Maintains safe operation. |

When you are using a paper cutting guillotine, it is important to stay focused. Distractions can lead to accidents, so make sure you're paying attention to what you're doing. No texting, no chatting, just cutting. And if you're tired, maybe it's time to take a break and come back to it later. It's also essential to keep the blade sharp. A dull blade requires more force, increasing the chance of a slip-up. If you're not sure how to sharpen the blade, it's best to have a professional take care of it. Finally, always store the guillotine safely when not in use. Keep it away from kids or anyone who might not know how to use it properly.

I think we can all agree that being safe is the priority. Treat it like any other piece of machinery, be mindful, and take precaution. I'm not trying to scare you, but a little bit of caution goes a long way. I've seen people use these machines for years with no issues because they're careful and respectful. Take the time to learn the proper techniques, and always double-check that everything is in place before you make that cut. It's better to be safe than sorry, especially when sharp blades are involved. And remember, if something doesn't feel right, stop and take a look, do not force it.

Paper Cutting Guillotine: From Office to Industry

Paper Cutting Guillotine: From Office to Industry

So, we've talked about the basics, but let's zoom out a bit. Paper cutting guillotines aren't just for small offices or classrooms. They are actually used in a ton of different places, and the scale of these machines varies wildly. You've got your standard desktop model, which is great for cutting a few sheets of paper for a presentation or a craft project. But then there are these massive industrial guillotines that can slice through huge stacks of paper like it's butter. These are the workhorses of the printing and packaging industries, where precision and speed are absolutely key. Think about newspapers, magazines, even cardboard boxes - a paper cutting guillotine had a hand in making those.

The transition from office to industry is quite a leap, not just in size, but in technology too. Industrial paper cutting guillotines have all sorts of bells and whistles. They often have motorized blades, automatic clamping systems, and even digital interfaces that let you program precise cuts. These machines are designed to handle large volumes of work with minimal human intervention. You can think of these industrial guillotines as the equivalent of a factory assembly line for paper. It's pretty amazing to see how far the design has come from those early hand-operated models. It shows that a simple idea can evolve to meet the demands of a complex industry. And it's a testament to human ingenuity, always trying to make things faster, better, and more efficient.

Type | Typical Use | Key Features |

|---|---|---|

Desktop Guillotine | Office, classroom, home crafts | Manual operation, compact size, suitable for small stacks of paper. |

Industrial Guillotine | Printing, packaging, paper industry | Motorized blade, automatic clamping, digital controls, high-volume cutting capability. |